Department of Composite

The department of composites of IPPI is a recognized center of excellence for research, teaching and training in the field of polymer composite materials. The department is actively engaged in conducting various research projects for automotive, public transport and civil engineering sectors in Iran.

The main goal of the department is to conduct research on polymer composite materials and implement them in country's various industrial sectors. In terms of education and training, the department offers a range of research degrees (M.Sc., Ph.D.), Continuing Professional Development (CPD) programs including conferences, short courses and workshops.

Selected Current Projects

- Composites pipe repair knowhow

- Nanocomposites active packaging technology

- Manufacturing knowhow for composites solid lubricant

- Preparation and 3d printing of continuous fiber thermoplastics

|

Selected Completed Projects

|

|

Design and construction of FRP re-bar manufacturing machine via pultrusion and filament winding

|

|

Whole process and manufacturing knowhow for pultrusion technology (Natural fibers, epoxy, phenolic, internal release system)

|

|

Toughening technology for thermoset resins (Unsaturated Polyester (UP) and epoxy) for industrial applications

|

|

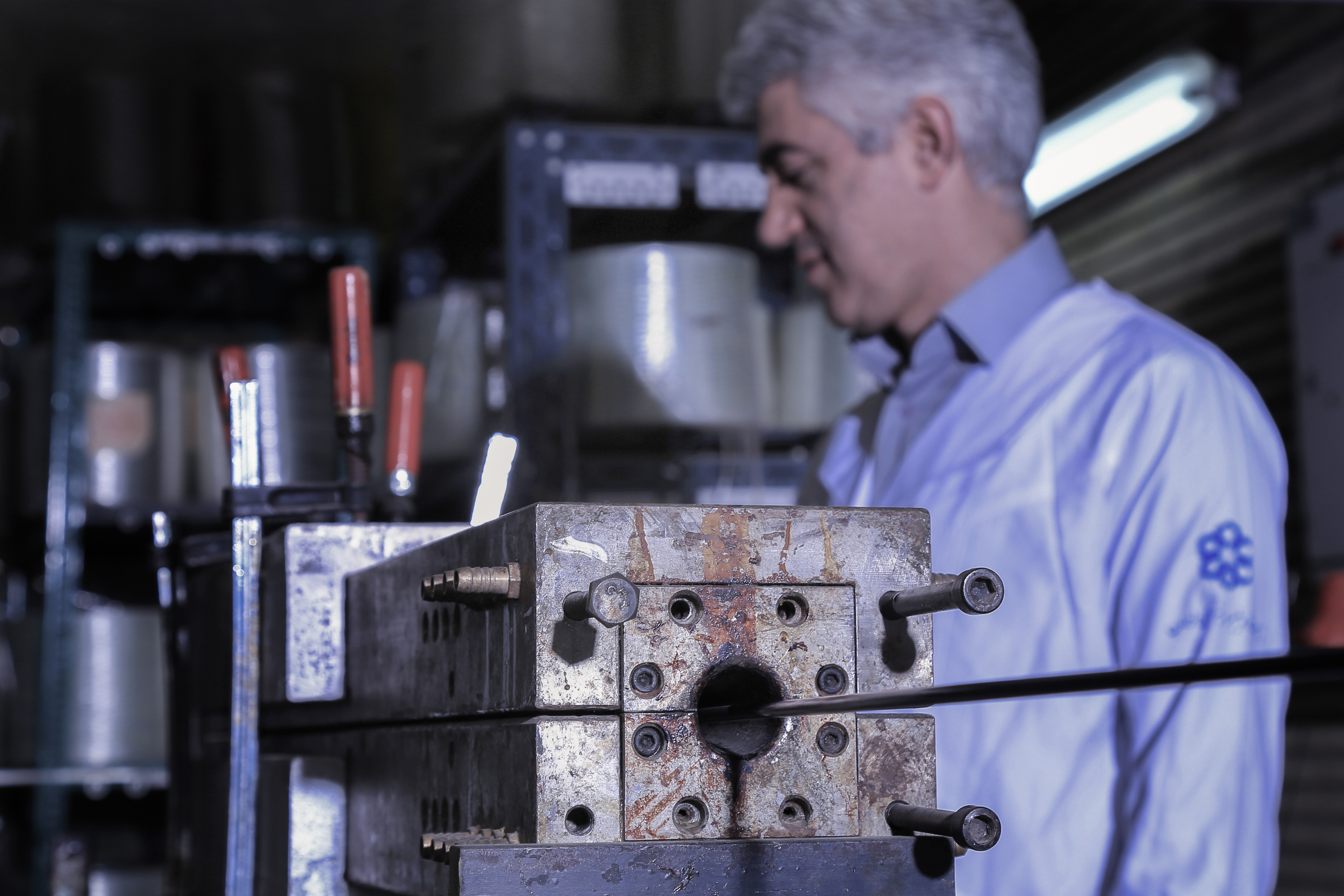

Design and manufacture of a resin transfer molding system and study of variable parameters

|

|

Design and fabrication of honeycomb sandwich panels for building applications

|

|

An experimental and numerical study of RTM process variables

|

|

Strengthening of structure using advanced composite materials

|

|

The compounding of phenolic - NBR foams as a heat insulator

|

|

Manufacturing knowhow for fast cure phenolic compounds

|

|

Design and construction of high velocity impact test facility

|

|

Design and fabrication of Fiber Metal Laminates (FMLs)

|

Facilities

- Gel timer

- Autoclave

- Viscometer (Brookfield and Ford cup)

- Homogenizer

- Densitometer

- Hot press (3, 15, 70 and 150 tons)

- Muffle furnace

- Vacuum mixers

- Corona discharge equipment

- UTM (tensile, compression, flexural

& ... testing machine)

- Rockwell and Barcol Hardness Testers

- Conventional and Vacuum Ovens

- Electronic Data Logging System

- High Velocity Impact Tester (Gas gun)

- Grinding Equipment (Jet mill & Pin mill)

- Pultrusion machine (in-house designed)

- Lab-scale prepreg machine (in-house designed)

- Resin injection and gel-coat spray equipment

- Compression moulds for molding compounds

- HYPA Ject MKIII and RTM Development Package

|

|

Academic Staff

Experts

|