Polymerization Catalysts Department

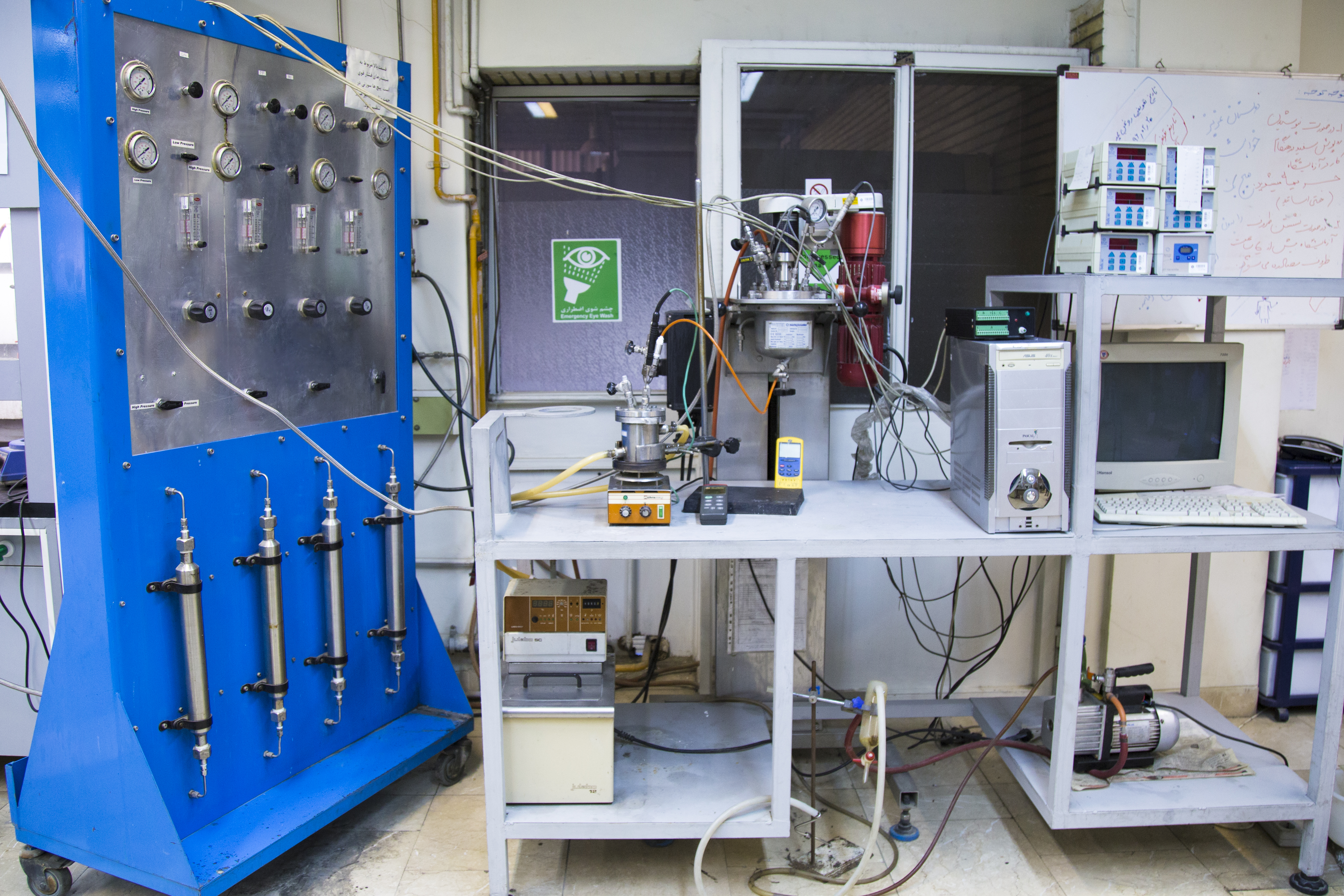

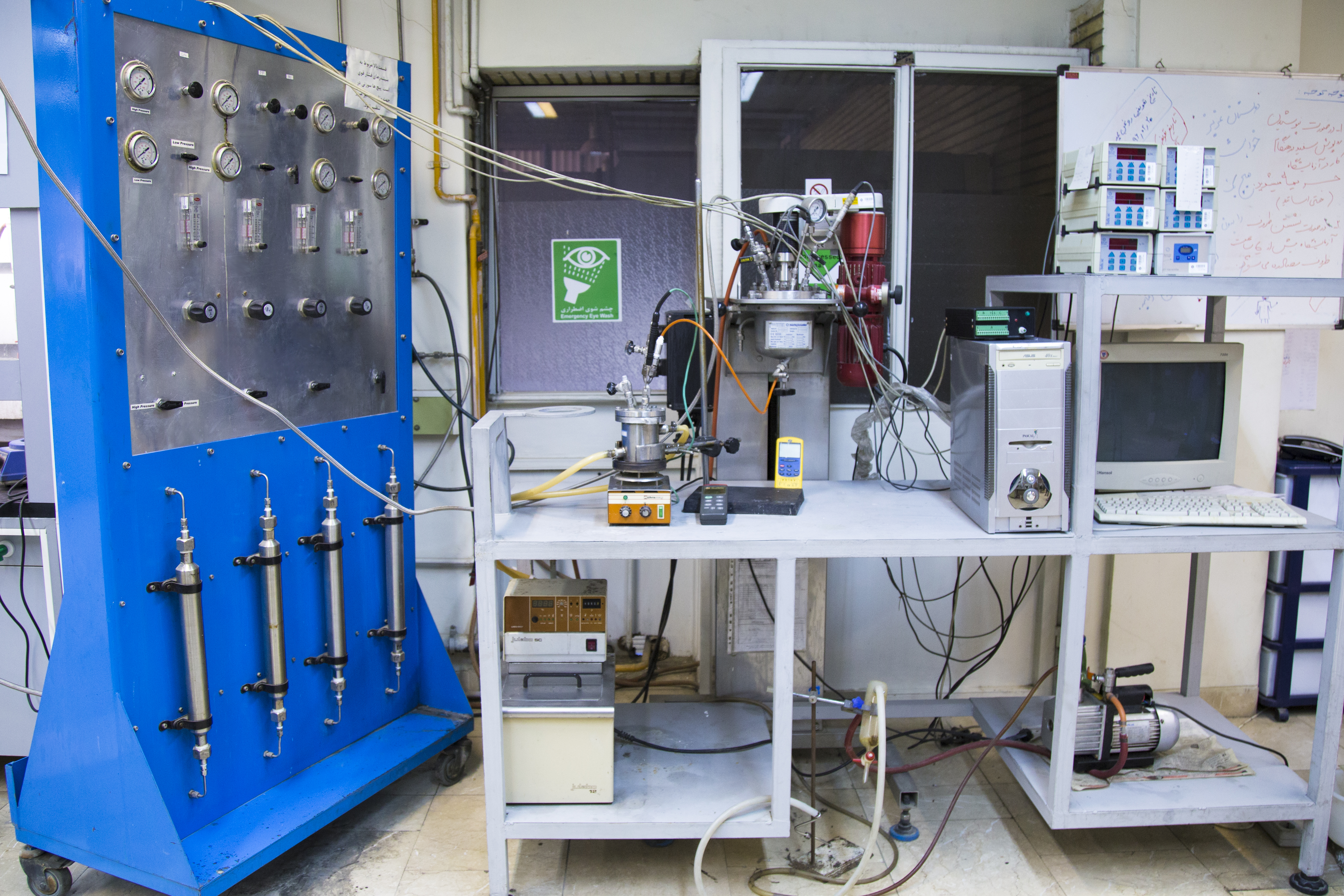

Working area

The main aim of this department carry out basic research on preparation of three types of transition metal based catalysts, for olefin polymerization. These catalysts which are based on mono and bi-supported Ziegler –Natta, metallocene and late transition metals catalysts. The first two types of catalysts are widely used for the manufacturing of a large variety of polymers including polyethylene, isotactic polypropylene and copolymers of ethylene and propylene. Late transition metals catalysts which allow the combination of polar monomers with non-polar olefins and thus lead to innovative materials.

|

Current Research Projects

|

|

Preparation of Palladium catalysts based-organic ligands for α-olefin polymerization or α-olefin copolymerization with polar monomers

|

|

Synthesis of Neutral Nickel or Palladium complexes and ethylene copolymerization with polar monomers

|

|

Preparation of Ni α-diimine catalysts bearing different ligands via a novel method

|

|

Preparation of polymeric antioxidants based on natural stabilizer

|

|

Preparation of metallocene catalyst for copolymerization of ethylene-propylene rubber

|

|

Preparation of metallocene catalyst for synthesis of cyclic olefin copolymer (COC)

|

|

Synthesis of late transition metal heterogeneous catalyst based on Nickel for ethylene polymerization

|

|

1-hexene polymerization by coordination catalysts.

|

|

Preparation of Silicon oil micro-emulsion containing functionalized silica and application as antifoaming agent

|

|

Completed Projects

|

|

Preparation of Ziegler-Natta catalyst with spherical support (MgCl2.nEtOH) for propylene polymerization in 5 kg scale

|

|

Copolymerization of ethylene-1-butene using SDX catalyst and characterization of molecular structure and relationship between structure and properties

|

|

Polymerization of ethylene using metallocene catalyst and investigation of properties and structure of produced polymers

|

|

Preparation of metallocene and beyond metallocene catalysts for α–olefins polymerization in lab scale

|

|

Preparation of high activity mono and bi-supported Ziegler-Natta catalyst for slurry polymerization of ethylene and propylene

|

|

Preparation of high activity mono and bi-supported Ziegler-Natta catalyst for copolymerization of EPR

|

|

Study of butadiene polymerization using non-supported/bi-supported SiO2/MgCl2 Ziegler-Natta catalyst with low Cis isomer content

|

|

Terpolymerization of ethylene/propylene and diene monomer (EPDM) elastomer using homogenous Ziegler-Natta catalyst system (VCl4/TiBAL)

|

|

Preparation of Ziegler-Natta catalyst for ultra-high molecular weight polyethylene and polymerization

|

|

Modification of MgCl2 support morphology with alcohol for spherical catalyst preparation and then polymerization of ethylene and propylene with these catalysts

|

|

Preparation the PZ catalyst for polymerization of ethylene that used in Bandar Imam Khomeini petrochemical complex

|

|

Preparation of Ziegler-Natta/metallocene catalysts hybrid for ethylene polymerization and preparation bimodal polyethylene

|

Facilites

The specialized laboratory of Catalyst Department is equipped with instruments necessary for the research and experimental preparation of catalyst and polymerization of ethylene, propylene, copolymerization of ethylene/propylene and terpolymerization of ethylene/propylene and diene monomers in addition to utilization of the general Catalyst Department equipped with several reactors in different volumes and required instruments for catalyst synthesis and polymerization. These include the following:

|

- Buchi laboratory reactor (up to 20 bar pressure and 250°C temperature with press flow controller

- Circulator (from -40 to 250°C) Proline heating thermostats

- Balance and Density Determination kit

- Vacuum oven box

- Rotary evaporator

- Dry box

- Set up for spherical support of MgCl2.nEtOH preparation

- UV cabinet test

|

|

Academic Staffs

Experts

Photo

|

First name

|

Last name

|

Post

|

E-mail

|

Phone number

|

|

Maryam

|

Beheshti

|

Laboratory expert

|

M.Beheshti@ippi.ac.ir

|

48662166

|

|

Ali

|

Farhadi

|

Laboratory expert

|

A.Farhadi@ippi.ac.ir

|

48662019

|

|